Our process modeling software program in the dimensions-up Suite allows you to obtain these aims and accelerate process advancement whilst dealing with significantly advanced processes.

Achieve insight into response mechanisms for deep reaction being familiar with that could be leveraged for best processing

Backed by our remarkable consumer assistance and schooling, Scale-up Suite empowers corporations to gain deep process awareness and accomplish successful production in their items.

Scale-up Suite�?is a leading provider of process improvement software for the global pharmaceutical and chemical industries.

Use mechanistic models to forecast situations that optimize generate and reduce impurities in artificial natural processes

Forecast the efficiency of each unit Procedure just before Just about every marketing campaign to make sure achievements on scale-up from lab to plant.

Transferring a process across scales will usually impression the Actual physical prices inside the synthesis, for instance mixing, warmth transfer, and mass transfer. Understanding the influence of these charges on the process is important to building the process to function efficiently and robustly even though producing high quality items at new scales.

Quickly produce response kinetic models from chemical instinct and customary lab facts to design best reactions.

Our process modeling software in the Scale-up Suite supplies an uncomplicated-to-use and detailed System for creating calculations and performing simulations that may account for your physical prices, making certain a correct first time scale-up and productive tech transfer.

We're committed to continuing to deliver the wonderful merchandise and buyer help that our clients have arrive at be expecting from Scale-up Techniques and look ahead to introducing the global strengths of METTLER TOLEDO.

Process calculations and simulations that may be made use of across all scales, enabling accelerated improvement and right first time scale-up.

The mix of our greatly made use of Scale-up Suite�?process enhancement and scale-up program with METTLER TOLEDO's marketplace-leading services for Organic and chemical process growth generates one of the most extensive offerings for these important purposes from the pharmaceutical and chemical field.

Mixing calculation applications aid scale from lab reactors which include Ambr® 15, shake flasks, vials, and rocked/wave baggage to stirred tank reactors

As read more a chemical process is designed, much more product have to be produced to at some point reach industrial production requires.

METTLER TOLEDO is committed to not merely protecting carbon neutrality for our operations but in addition to establishing science-based mostly targets to drive an absolute reduction of greenhouse gasoline emissions throughout our functions and check here provide chain.

In depth library of Completely ready-to-use simulation instruments produced by sector experts, readily available to all end users

Quickly completely transform routinely gathered process, PAT, and offline analytical info into kinetic types that enable increased reaction being familiar with with limited time and here materials

Develop bioreactor products to support the prediction of glucose and DO ranges, pH, and titer at Each and every scale, leveraging mixing tools to make sure uniform spatial distribution

Search a custom made portfolio, accessibility estimates, and control your installed devices on our read more prolonged digital platform.

Process scale-up usually refers to increasing the production ability by working a chemical process in bigger equipment. For get more info example, transferring a process within the lab scale into a pilot plant or from a pilot plant to an entire-scale manufacturing plant.

Often, a chemical process is scaled up various moments, more than orders of magnitude, from small lab bench scale to medium pilot plant services to big comprehensive-scale production crops.

Guarantee adequate mixing devoid of extreme shear in functions starting from media advancement/prep to UF/DF, avoiding batch failures and produce decline

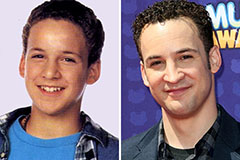

Ben Savage Then & Now!

Ben Savage Then & Now! Andrea Barber Then & Now!

Andrea Barber Then & Now! Andrew Keegan Then & Now!

Andrew Keegan Then & Now! Kelly Le Brock Then & Now!

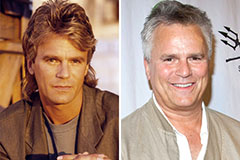

Kelly Le Brock Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!